Angebot anfordern

Bitte teilen Sie uns Ihre Kontaktdaten mit, wir melden uns bei Ihnen

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information

We come from the tube, so to speak: The nucleus of CTA GmbH was Albert Kienzle GmbH & Co. KG, a tube manufacturer that also produced rubber solutions and patching tools. In 1996, Kienzle GmbH was taken over by the Tubex Group, one of the world’s leading tube manufacturers. CTA GmbH has been an independent subsidiary since 2005. We are the filling specialists within the Tubex Group and have the experience and expertise to fill chemical-technical products in liquid to highly paste-like form into almost any conceivable packaging.

Foundation of Albert Kienzle GmbH & Co. KG (a company for rubber solutions and patching tools), the CTA here was a small department of the aluminium tube manufacturer.

Takeover of Albert Kienzle GmbH & Co. KG by Tubex Holding.

CTA GmbH becomes an independent subsidiary of Tubex Holding and receives ISO 9001 certification.

Establishment of a laboratory for the development of own products and the optimisation of customers' own formulations. Foundation of the packaging development department.

Extension for specialised filling of greases, oils, cleaning agents or even 2-component adhesives in sealed-rim bags.

Start of construction of the new location in Ludwigsburg. Start of project CONTRACT FILLING 4.0.

Move to Ludwigsburg. Further development of the Contract filling 4.0 project in the form of digitised production data acquisition.

"Our success is based on the qualifications and performance of our employees. We are proud of this."

We offer our customers quality and process reliability – and we can also prove it. Our company is certified according to ISO 9001 for quality management systems, ISO 14001, the globally recognised standard for environmental management systems, and ISO 50001, the international standard for energy management systems.

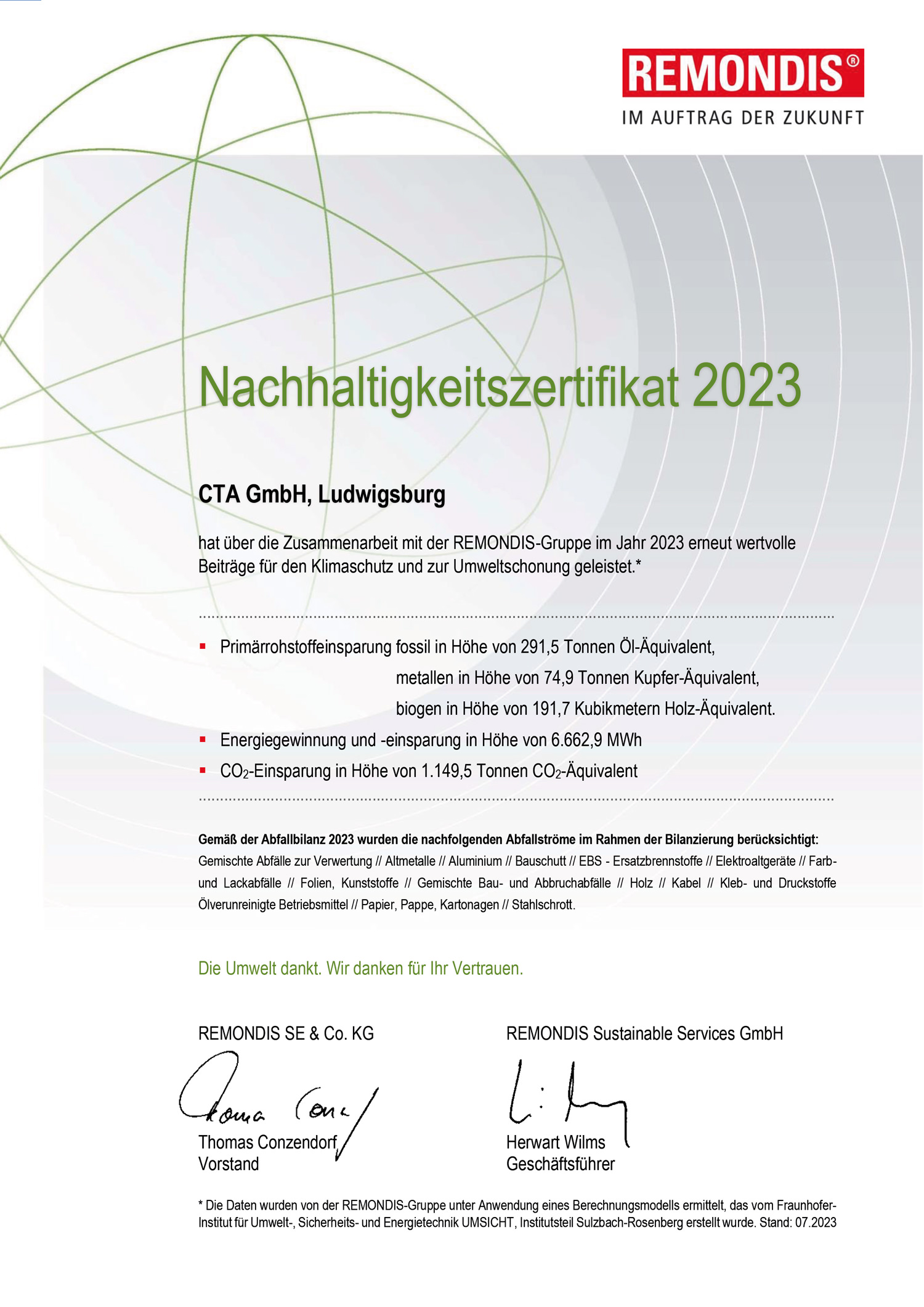

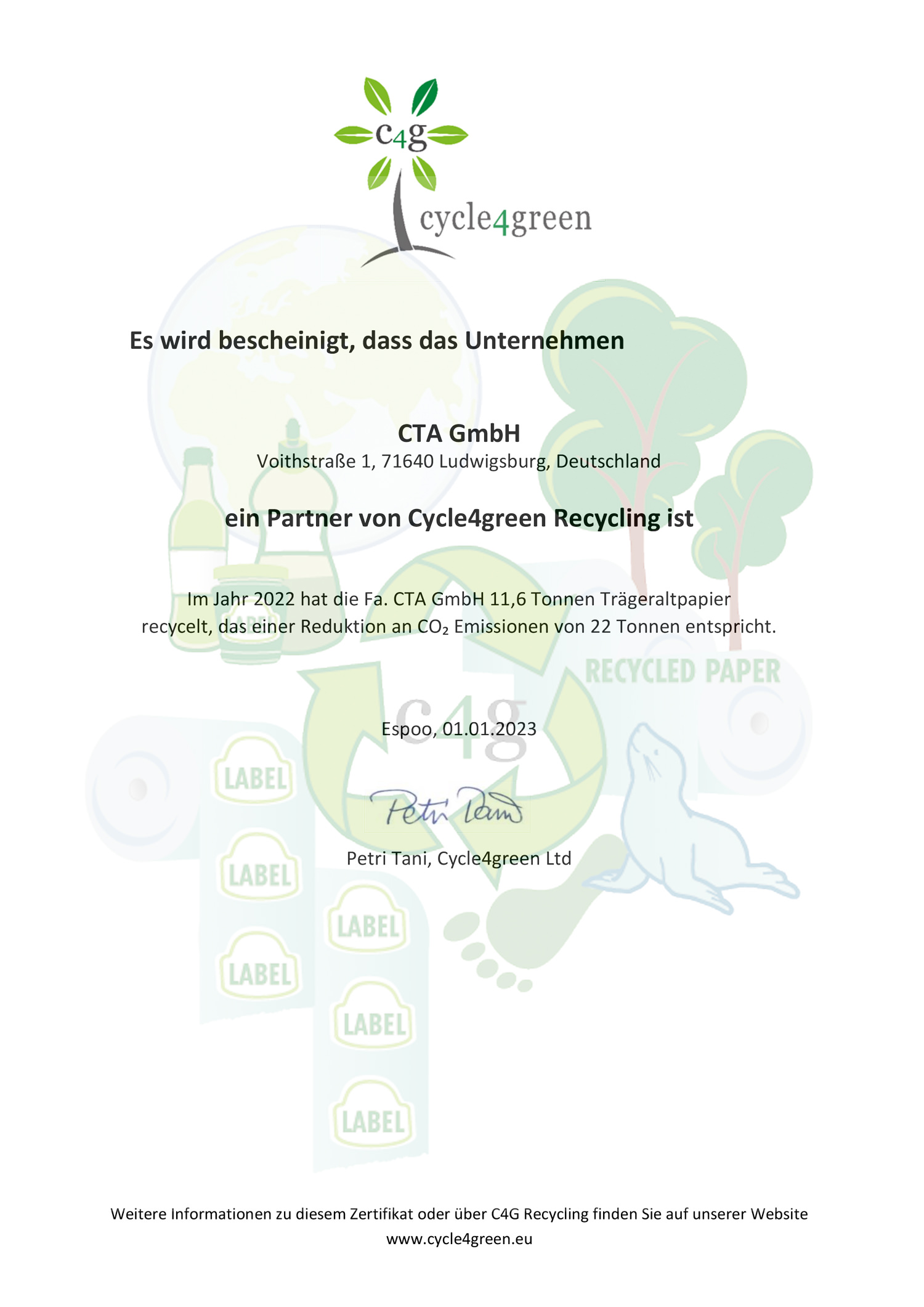

Since our company moved to Ludwigsburg in 2018, CTA GmbH has had its own waste management department. The task of this department is to use all resources as sparingly as possible and to repeatedly examine every process according to environmental protection criteria. The sustainability certificate awarded in 2020, which is based on the calculation method of the Fraunhofer-Institut für Umwelt-, Sicherheits- und Energietechnik UMSICHT (Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT), shows that we are on the right track when it comes to sustainability.

Avoidance of waste

Optimal preparation for reuse

Sustainable recycling processes

Other utilisation concepts

Waste disposal

Separation and recycling of sorted plastic waste

Collection of empty printer cartridges and toner cartridges for refilling or delivery to the recycling industry

Modernisation of work equipment to reduce energy consumption, e.g. the compressor for the compressed air system

Renewal of the transformer station to increase environmental compatibility

Bitte teilen Sie uns Ihre Kontaktdaten mit, wir melden uns bei Ihnen

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationBitte teilen Sie uns Ihre Kontaktdaten mit, wir melden uns bei Ihnen

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information

Today we would like to inform you about our new manufacturing site for down packing at CTA USA LLC. Baltimore.

After all the hurdles that have arisen in the last few weeks, we can now proudly look back on a successful down packing. Last week the time had come and our colleagues from Germany, together with their colleagues from the USA, carried out the first serial down packing of 2 component cartridges. We would like to share this further milestone in the history of CTA with you using a few impressions from last week and are now looking forward to taking the next steps in the USA together with you and will be happy to answer any questions you may have.

CTA USA LLC.

979 Corporate Blvd, Linthicum Heights, MD 21090

E-Mail: info@cta-chem.com, Phone: +1-410-855-6131